Researchers from the German Fraunhofer Institute are studying a new way of packaging the battery cells that significantly lighten their weight, and can achieve autonomy of up to 1000 kilometers in electric vehicles.

Nowadays a battery of an electric car is formed by a large number of cells. Each one of them has its own housing and is connected to the others, and to the sensor system to monitor its status, by means of cables. The result is that more than half of the battery space is occupied by these «auxiliary systems», which reduces the packing density. To this problem the electrical resistances that take place in the unions of the cells are united, that reduce the power.

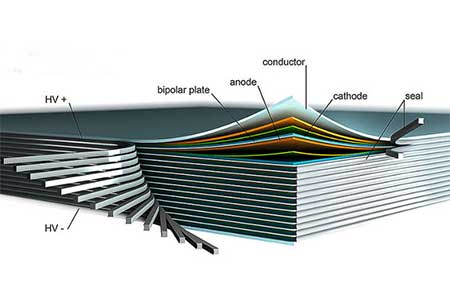

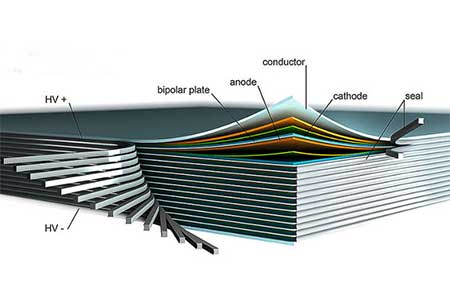

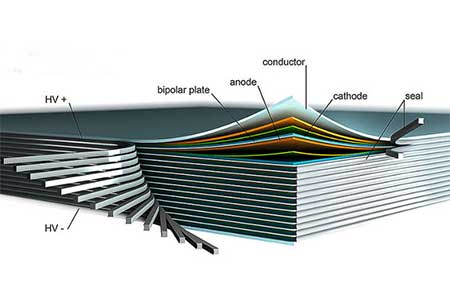

The Fraunhofer Institute for Technology and Systems of IKTS ceramics, in Dresden, under the EMBATT brand, has transferred the technology from the fuel cells to the lithium battery. The design allows the cells of the batteries to be stacked directly on top of each other, without separation, eliminating the structure and wiring, by connecting them directly. This is achieved by increasing the number of cells that fit in the same space. With this design the current flows over the entire surface of the battery and the electrical resistance is reduced.