Transportation is one of the most important human needs. Nowadays, in our civilization it is so vital that we depend totally on it, both to move and to transport our resources, be it water, food, or any other basic need.

For this reason, it is logical to think that the automotive industry seeks to develop technologies that allow a better performance. It is expected that in the near future this economic sector will benefit enormously from nanotechnology and nanomaterials.

Global expectations of lower emissions and fuel savings are creating huge demands for lightweight, durable and low-cost materials to replace expensive metals and compounds, and nanotechnology can help meet those demands.

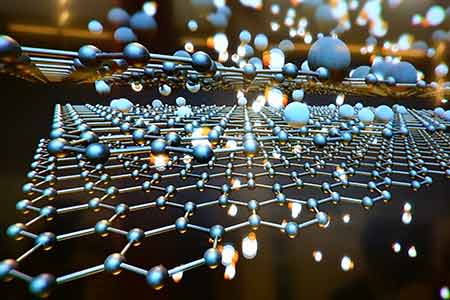

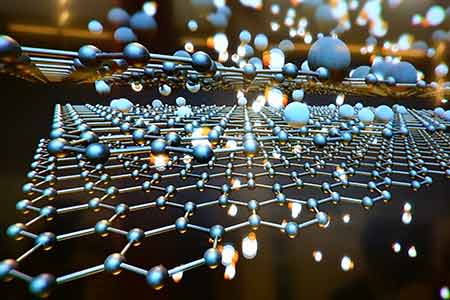

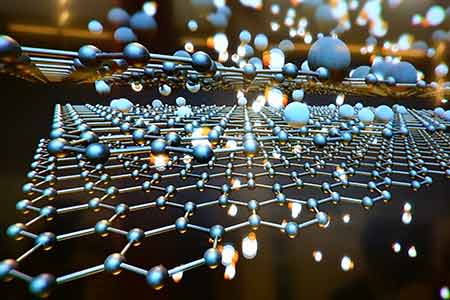

Scientists led by Johns Hopkins University have developed a new method to increase the reactivity of ultra-thin nanosheets, with only a few atoms of thickness, an advance that can make fuel cells for hydrogen cars cheaper in the future.

The research, published in the journal Science, promises faster and cheaper production of electric power using fuel cells, and also chemicals and bulk materials such as hydrogen.

The new method focuses on finding the right amount, to evaluate how much metal would be required for the fuel cell electrodes. The technique uses the forces on the surface of a metal to identify the ideal thickness of the electrode.

«Each material experiences a tension on the surface due to the breakdown of the crystalline symmetry of the material at the atomic level. We discovered a way to make these crystals ultrafine, thus decreasing the distance between the atoms and increasing the reactivity of the material, «says Chao Wang, assistant professor of chemical and biomolecular engineering at Johns Hopkins University and one of the corresponding authors of the study.